Robotic welding machines

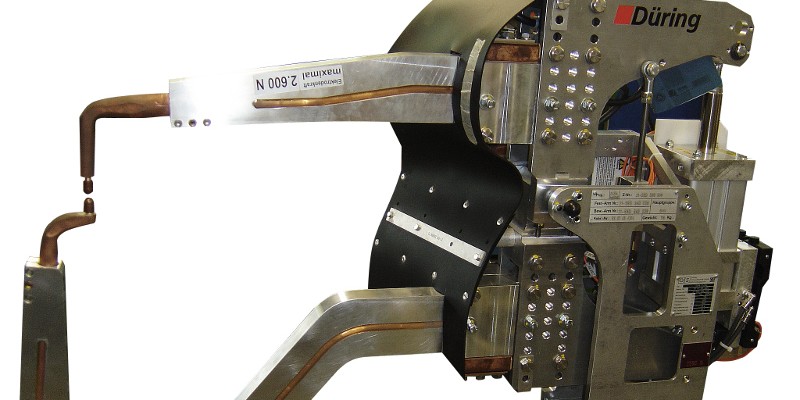

Düring manufactures robotic grippers with in-house machining on its modern CNC machines. Automatic clamps are fast, accurate and low cost. All clamps are developed with certified, high-strength materials to withstand extreme working conditions. Düring produces clamps with individual technology and characteristics, according to the needs of your project.

Pneumatics

Pneumatic welding clamps for Robots

In Düring grippers with pneumatic drive, the force is generated by actuators powered by compressed air. This type of drive is effective due to its ease of implementation, as every industry has a compressed air network. The forces can be changed and regulated according to the variation in pressure applied to the pneumatic cylinder.

Pneumatic welding tongs are characterized by high work rate, low cost and easy maintenance.

Rollergun

Continuous welding machines Seam Technology GmbH

Düring seam resistance welding machines are fast and flexible. Rotating electrode plates weld different shapes of parts and types of materials.

Düring seam welding clamps meet all welding requirements and standards for continuous welding machines, the electrodes are manufactured according to our customer's needs.

Servoelectric

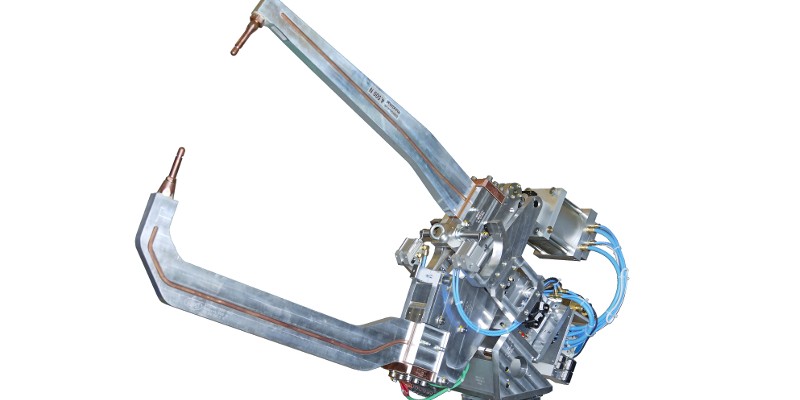

Servo Electric Welding Tweezers for Robots

In Düring grippers with electric servo drive, the force is generated by intelligent electric actuators. This type of drive is extremely silent and energy efficient like a pneumatic actuator.

Servo electric welding tongs have the characteristic of supporting high work rate. Due to the very low response time, cycle times are reduced compared to conventional pneumatic grippers. The full welding capacity available in a short time means that the process remains constant.

Further advantages of Düring servo electric grippers:

– The electrodes are gradually activated, preventing deformation of the sheets;

– The welding points form a precise lentil;

– Develop high working forces at the welding points;

– When welding there is practically no spatter.

Servopneumatics

In Düring grippers with pneumatic servo drive, the force is generated by intelligent actuators powered by compressed air. This type of drive is effective due to its ease of implementation and high control. Gripper forces and openings can be individually programmed and customized. Each welding point has its own programming.

Servo pneumatic welding tongs have the characteristic of supporting high work rates and reducing production time, by optimizing their work, avoiding stops in the welding cycle to reposition the electrodes.